Any serious user or collector agrees that nothing is more important than a fountain pen’s nib, no matter how intricate the outer design of the pen might be: if the nib doesn’t perform as expected on paper, the pen serves as nothing more than a decorative piece. I often compare a nib to a watch movement, and I can tell whether a brand has prioritized this small component by the way it glides across the paper. However, considering the technology today’s brands have access to, there’s more to a nib than just its utilitarian side—such as the size, the shape, the material it’s made from, and, of course, the design. Today, we take a closer look at the anatomy of a nib—what makes one stand out, and what details you should consider when buying your first or next fountain pen.

Brief Evolution of The Fountain Pen Nib

I’m often impressed by the effort and dedication our ancestors put into developing what we now tend take for granted—but to truly appreciate it, we must understand the challenging evolution of the nib to this day. The nib traces back to antiquity, beginning with reed pens in ancient Egypt, followed by quills from the 6th century onward.

History reveals that metal nibs first appeared in the late 18th century, gaining commercial traction around 1822 when English manufacturers like James Perry and Josiah Mason began mass-producing steel dip nibs. These early nibs were flexible but required frequent dipping.

The real transformation came with the advent of the self-contained fountain pen in the mid-to-late 19th century, but it was Lewis Waterman’s patented feed system in 1884, which allowed the nib to draw ink continuously from a reservoir, that marked the birth of the modern fountain pen.

By the 1920s–1940s, nibs reached a technical and artistic pinnacle. Brands like Waterman, Swan, and Wahl-Eversharp produced hand-crafted gold nibs with extraordinary flex and responsiveness, often with engraved scrollwork and ebonite feeds perfectly tuned to each nib.

Post-WWII, the emphasis shifted toward durability and mass production. Stiffer nibs became the norm, and gold content was reduced. Today, brands like Sailor, Pilot, and Nakaya preserve traditional nib craftsmanship, while companies like JoWo and Bock supply precision-ground nibs at scale.

Though the golden age lies in the past, modern artisans continue to honor the legacy of the nib—constantly challenging the status quo and exploring new forms of decoration.

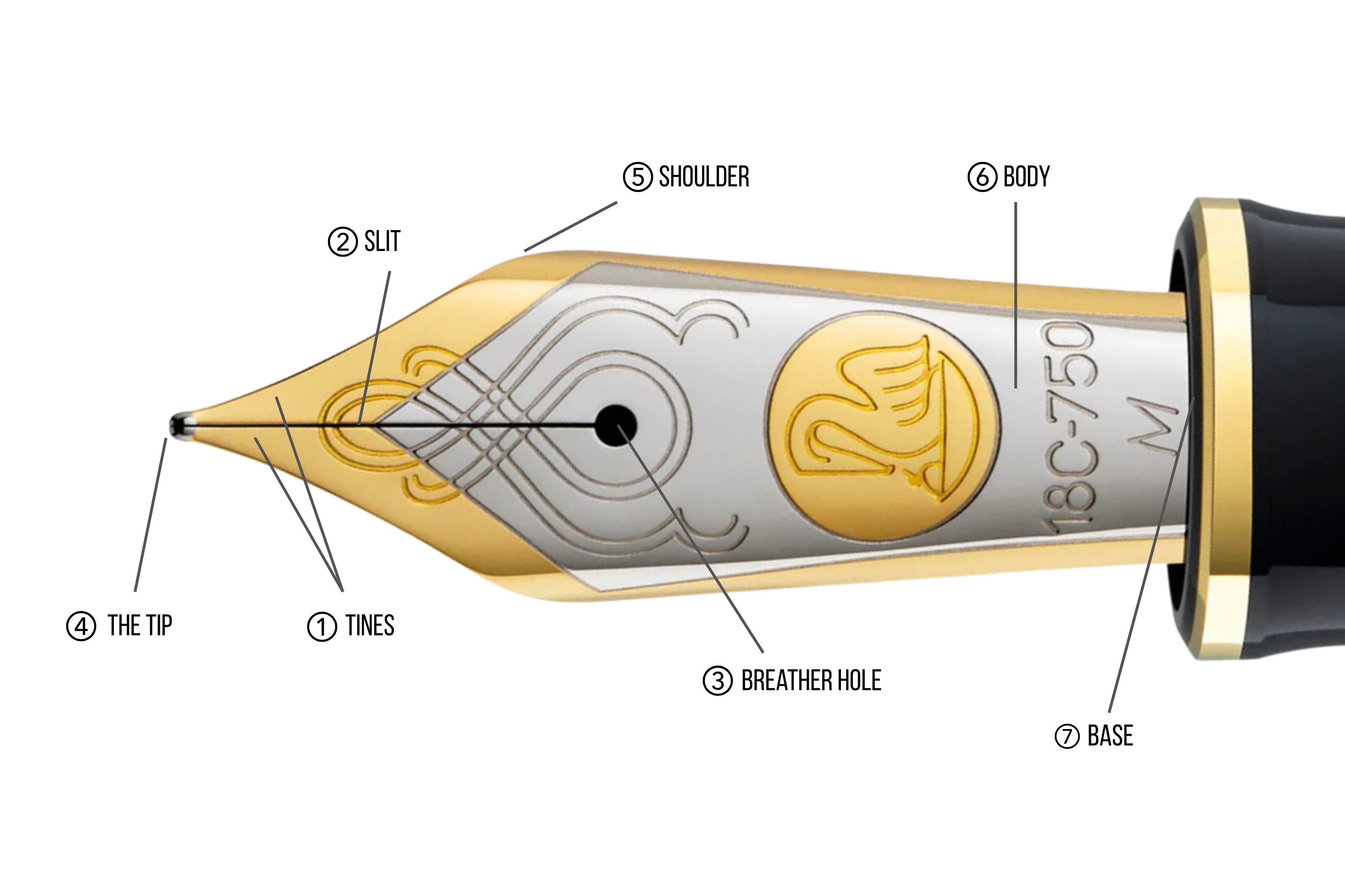

The Anatomy of a Nib

Everyone new to the hobby might see the nib as deceptively simple at first glance, but it takes Montblanc 35 precise steps to produce one. In fact, the engineering behind this little component you see plays a critical role in the writing experience. A small crack in the feed or misaligned tines, and the whole writing experience is ruined, that is, if you still manage to get the pen writing.

1. The Tines

The tines are two symmetrical prongs that form the tip of the nib, created by slicing a central slit into the metal. As you write, the tines flex microscopically to allow ink to flow between them. On soft or flexible nibs, the tines spread under pressure, producing line variation, so you can explore different writing styles. Tine alignment is crucial: even a fraction of a millimeter off can cause scratchiness or inconsistent flow. Vintage flex nibs often had longer, thinner tines for greater responsiveness

2. The Slit

The narrow channel that runs down the center of the nib, from the breather hole to the tip, serves a vital function as it conducts ink from the feed via capillary action. The slit controls ink flow rate and pressure stability. A slit that’s too wide can flood the tip; too tight, and ink won’t flow properly. Some modern nibs use laser-cut slits for precision.

3. The Breather Hole (or Vent Hole)

The breather hole, or often called the vent hole is a small circular or decorative cutout placed where the slit ends, just before the body of the nib. It acts as a pressure equalizer and a stress relief point, preventing cracks at the end of the slit caused by flex or metal fatigue. While many It’s essential for maintaining consistent ink flow and ensuring the nib’s long-term structural integrity. On flex nibs, it also helps reduce metal fatigue from repeated bending.

4. The Tip (or Nib Point)

The tip or the nib point is that rounded ball of metal alloy welded to the end of the tines, then shaped and polished to create the actual writing surface. This is the part that makes contact with the paper and defines both line width and writing feel. Though often referred to as “iridium,” it’s usually a hard-wearing alloy. Its size, shape, and finish determine whether the pen writes fine or broad, smooth or toothy. Variations include round, stub, italic, architect, and more, each affecting ink shading, flow, and feedback differently.

5. The Shoulders

Moving on to the shoulders of the nib, which are the curved flanks located between the tines and the body. Their shape determines the nib’s stiffness or softness. What I noticed is that broad shoulders typically result in a firmer nib, while narrow ones often allow for more flex. The construction of the shoulders, combined with the overall thickness of the nib, influences whether the pen feels rigid, springy, or has a bit of bounce during writing.

6. The Body (or Nib Shank)

The body is the widest surface of the nib, often referred to as the nib shank. Most brands use this area to showcase their identity—whether it’s a logo, hallmark, nib size, or decorative engravings. While it serves an aesthetic purpose, this part of the nib also provides structure and stability. It rests on the feed, influencing both ink delivery and nib alignment. The thickness and contour of the body can also affect how the nib sits in the section and how it responds to writing pressure.

7. The Base (or Heel)

The base is the rear part of the nib that fits into the feed and the section of the pen. Its role is to secure the nib in place, usually by two methods: either friction or thermal bonding to the feed in the case of many reservoir pens. Proper attachment is essential for adequate ink flow and correct nib alignment. If misaligned, the nib may feel loose or unstable during writing, which can impact the writing experience.

Conclusion

Now that you understand the different parts of a fountain pen nib and how much know-how goes into making one, you’re better equipped to appreciate how a great nib influences performance on paper.

But I have learned that knowledge alone isn’t enough. So, whenever possible, test the nib before you buy it. Not only will you get a feel for how it matches your writing style, but you’ll also be able to spot any potential issues, from misaligned tines to inconsistent ink flow.

And if you’re ordering online, don’t hesitate to ask the retailer to inspect the nib before shipping. Even the finest nibs benefit from a final human check, and your writing deserves that extra care, because in the end, it will show in every word you put on paper.

Condividi:

- Click to share on X (Opens in new window) X

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to share on Pinterest (Opens in new window) Pinterest

- Click to share on Telegram (Opens in new window) Telegram

- Click to email a link to a friend (Opens in new window) Email

Leave a Reply